HISTORY

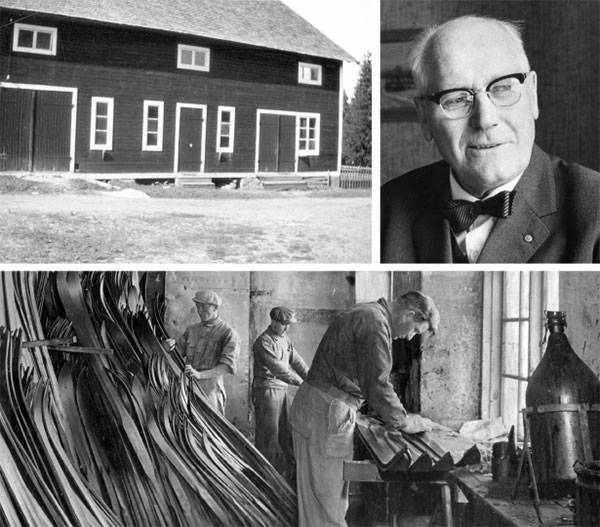

The start of a ski factory

Since Eric was good at marketing himself, the ski factory developed quickly, and in a few years had grown to 20 employees. A contributing reason for the development going so fast may be due to the fact that the Vasaloppet (large Swedish ski race) started in 1922 and a great interest in skiing also increased for the general public.

The military also became a major customer.

In 1927, the ski factory, which consisted of a large barn, in Arbrå burned to the ground. Then Eric thought that a ski factory should be located where there are good skiers. He and his wife Martha then moved to Hudiksvall where he started a new ski factory.

As the development was explosive, the premises soon became overcrowded. In 1936, Eric got hold of a property at “Varvet”, where the premises are still today. The workforce had then roughly tripled!

Still only skis were manufactured. The high season was autumn and winter, which meant that several employees made a living by fishing during the spring and summer.

The arrival of hydraulics

In 1947, they launched the world's first mobile hydraulic crane. Which was a major revolutionary advance in cargo handling.

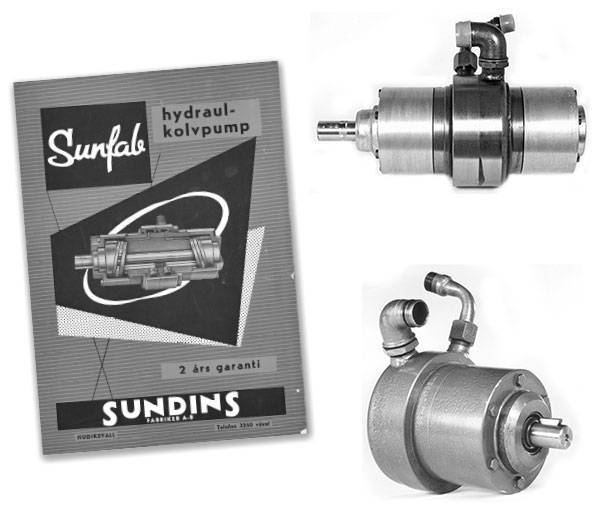

Development in HIAB was fast and to improve the standard of the hydraulic system, better pumps were needed. Eric Sundin was involved when the first hydraulic piston pump, Sunfab, was developed in 1954.

The youngest son Henry took care of the construction of pumps at Sunfab, while the two older sons Anders and Göran started working at HIAB. Göran built the sales network for HIAB in the USA when he got married and moved to Wilmington in 1963. Anders was an innovator and took care of the product development of the HIAB cranes.

Growth and the start of Sunfab

At the same time, housings was built in the eastern part of the city near the factory, in the form of villas and rental apartments for those who worked at Sundins Fabriker AB.

The Sunfab brand was first registered in 1952, to take care of all the various hydraulic products that were developed and manufactured by Sundins Fabriker in a separate company separated from skis and cranes.

The products manufactured at Sunfab were hydraulic pumps, complete hydraulic workshop presses and ski presses, electric power-packs, jacks, power take-offs for Scania trucks and agricultural tractors, transfer gears for dual pump assembly and much more.

Decisive choices

In addition, demand was constantly increasing, both for the Sunfab pumps and the HIAB cranes. It became too much for a family to handle by themselves. Therefore, HIAB was sold in 1965 to an investment company.

However, Eric Sundin continued to work at Sundin's factories until his death in 1975.

The middle son Anders took over responsibility for the operation of the ski factory.

When manufacturing skis, Eric Sundin invented a method of splicing the wood, so-called finger jointing, there was no more waste and the utilisation rate was increased. The ski timber must be free of twigs.

During the mid-70s, there were approximately 280 people employed at Sundins Fabriker. In the late 70's the market for finger jointing was deemed saturated and that branch was sold to a competitor at the time.

End of one era and focus on the next

In Sweden, the Goverment started a large ski factory in the city of Haparanda with the name “Sirius Skidor”. It was a contributing factor to that Sundin's and most of Sweden's other ski manufacturers having to wind down their production.

In 1989, Sundin's ski manufacturing was shut down and many jobs disappeared. Shortly afterwards, the Swedish Goverment sold the Haparanda factory to ELAN, which after a few more years shut down production and moved all their production back to Yugoslavia.

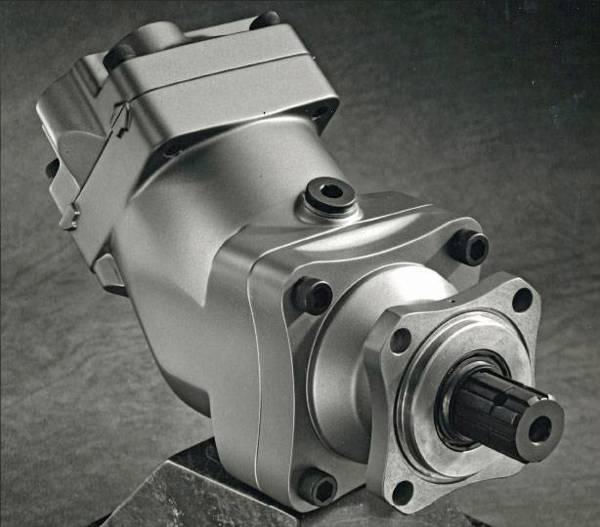

In the early 1990s, there were some years when the Swedish industry had a hard time. Sundins Fabriker changed its name to Sunfab Hydraulics AB. With the new share issue, Sunfab invested further and concentrated in truck hydraulics, where the market was the largest.

The well-known SC pump was developed and a hydraulic motor was also produced.

The 21st century and new challenges

In November 2006, the newly built part of the factory was inaugurated. Anders Växthus (Anders Greenhouse as in growth), became the appropriate name for the project, in memory of Anders Sundin.

It also invested in several new generation machines to gain greater efficiency. In order to meet today's high environmental requirements, the entire property is heated and cooled using geothermal energy.

The new premises of 3,500 square meters were built together with the old factory, got double ceiling height and a substantial loading dock.

Today, Sunfab is a well-known brand worldwide and approx. 90% of sales are exported to around 60 countries around the world.